What make our Ethylene Oxide sterilization equipment different?

- Using premium materials and components

For the manufacturing of our EtO sterilization equipment, we use material of construction made of top quality, coming from Europe. ATEX certified components are used and most of them also meet the SIL specifications (IEC61508) for a maximum reliability during the EtO chamber operations.

We deliver safe and high-quality equipment with a long-term viability.

- Accurate thermodynamic calculations

This aspect is very important and has a direct impact on the sterilization process results and time. In other words, it allows to give an optimal performance to the equipment.

- Safety PLC – ONYX control system

Unlike most of the EtO chamber manufacturers that propose a standard PLC for the control of their equipment, RSD uses a safety PLC. In our opinion, safety is not an option, it is a priority. The PLC is the brain of the installation, and we spare no expense to increase the safety.

- Development and manufacturing based on ATEX directive.

In view of the risks of the ethylene oxide gas (toxic, explosive...), we offer an equipment that is classified as zone 1 and 2 according to the ATEX directive.

The ATEX directive is one of the most stringent international directives for equipment used in a potentially explosive atmosphere. Thanks to our team, ATEX certificated level 1 and 2 Electrical & Mechanical for design and maintenance of installations with potential explosive atmosphere, we execute a deep ATEX expertise for every single EtO sterilizers we design, to ensure the maximum safety for our clients.

- High-technology vacuum pumps

The technology used is the liquid ring pump that is a state-of-the-art technology for the Ethylene Oxide sterilization process. Those pumps are both very safe (certified to work until zone 0 ATEX) and totally compatible with any sterilization cycle. In addition, this kind of technology does not require much maintenance.

- Robust and long-term guarantee

We offer a robust equipment based premium materials, rigid frames, advanced components and with state-of-the art design. Our Ethylene Oxide sterilization equipment have 15-years guarantee for the vessel and 2 years for the rest.

- Turnkey projects

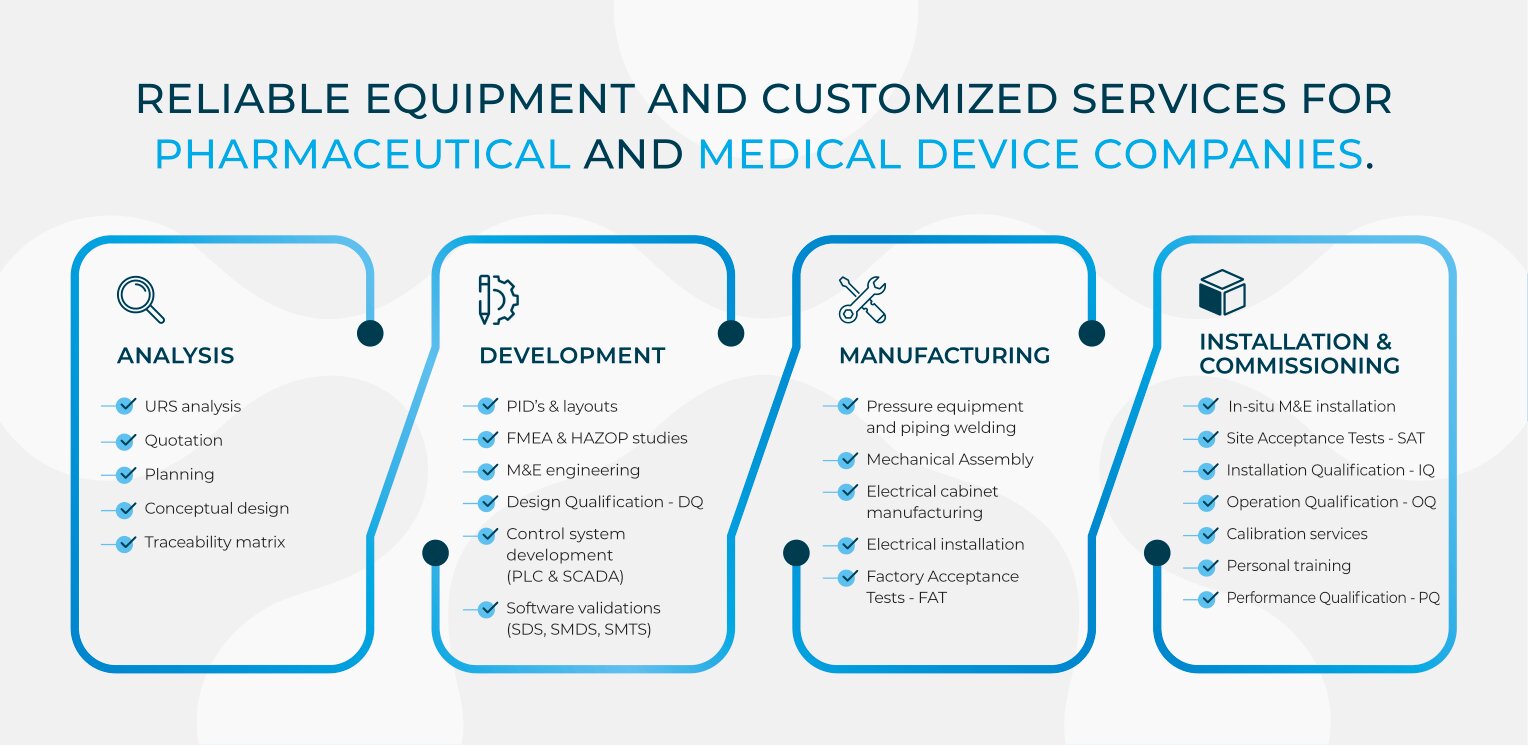

Working with us, you will have a single partner that gives you full support, controlling every step of the Ethylene Oxide sterilization project:

- Feasibility study

- Design

- Mechanical & Electrical engineering

- Manufacturing

- Control and programming

- In-situ installation

- Start up

- Qualification

With the aim to propose a complete EtO sterilization plant considering all your special needs.

Thanks to the fact that everything is designed and manufactured in the RSD premises (except the pressure vessel), we have a perfect control of the whole project.

Our commitment is to offer the highest quality for our sterilization equipment, based on EtO sterilization turnkey solutions, totally adapted to our customers’ needs, always including a high level of safety, reliability and efficiency.

For us, it is essential to offer high-quality and tailor-made services to create a trusted and close relationship with our customers.

RSD is always looking for improvement and innovation about EtO sterilization machine.