Different types of steam for sterilization

- Plant steam, or also called industrial steam.

- Process steam, called “clean” steam as well.

- Pure steam.

How are produced those different qualities of steam?

- Plant steam or industrial steam: the water used is a slightly softened water. The steam is produced by a conventional steel boiler. This steam is sterile but no clean because a lot of products and components coming from the steam distribution system contaminate the produced steam. It is for this reason that the plant steam cannot be in direct contact with medical and pharmaceutical products. The Plant / Industrial Steam is only kept for an indirect use, as thermal feeding.

- Process Steam or Clean Steam: the water used is obligatory a demineralized or osmosed water. The steam is produced by a stainless-steel boiler. In addition, any water supply or steam distribution system should be made of stainless steel.

- Pure Steam: the water used is should come from a double osmosed water even PPI. The steam is produced by a stainless-steel polished boiler with a design allowing a minimum retention.

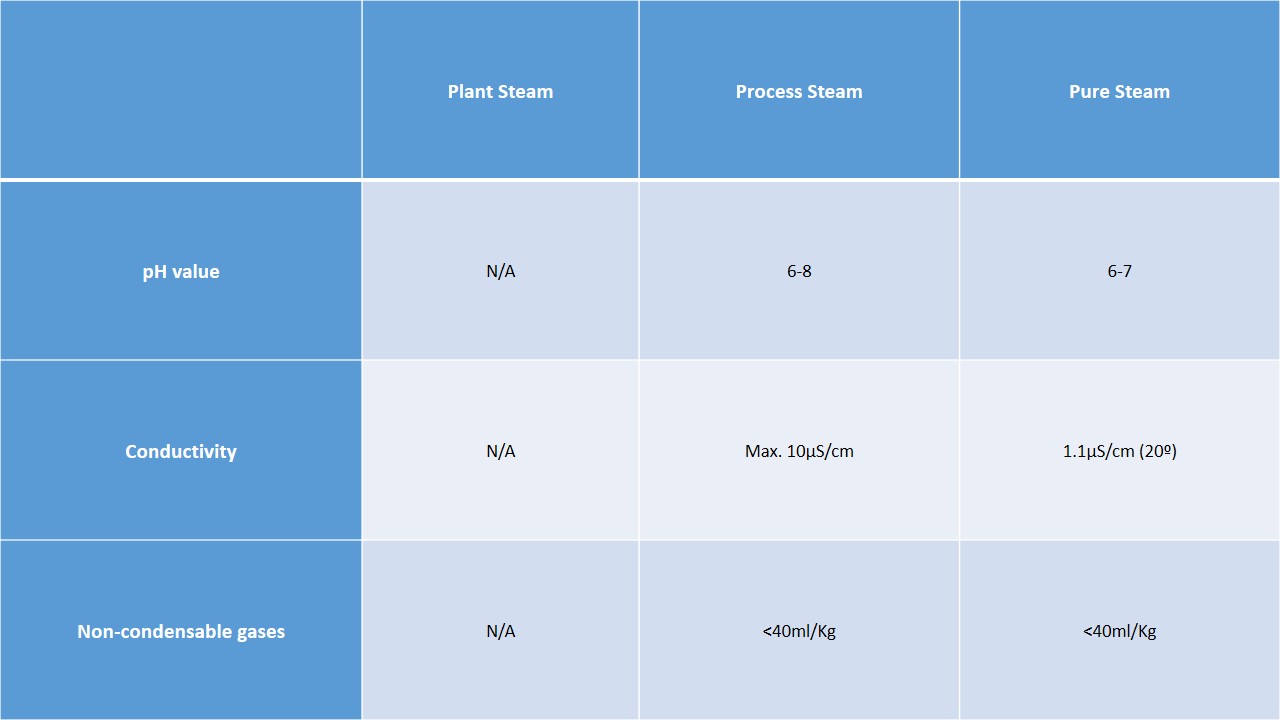

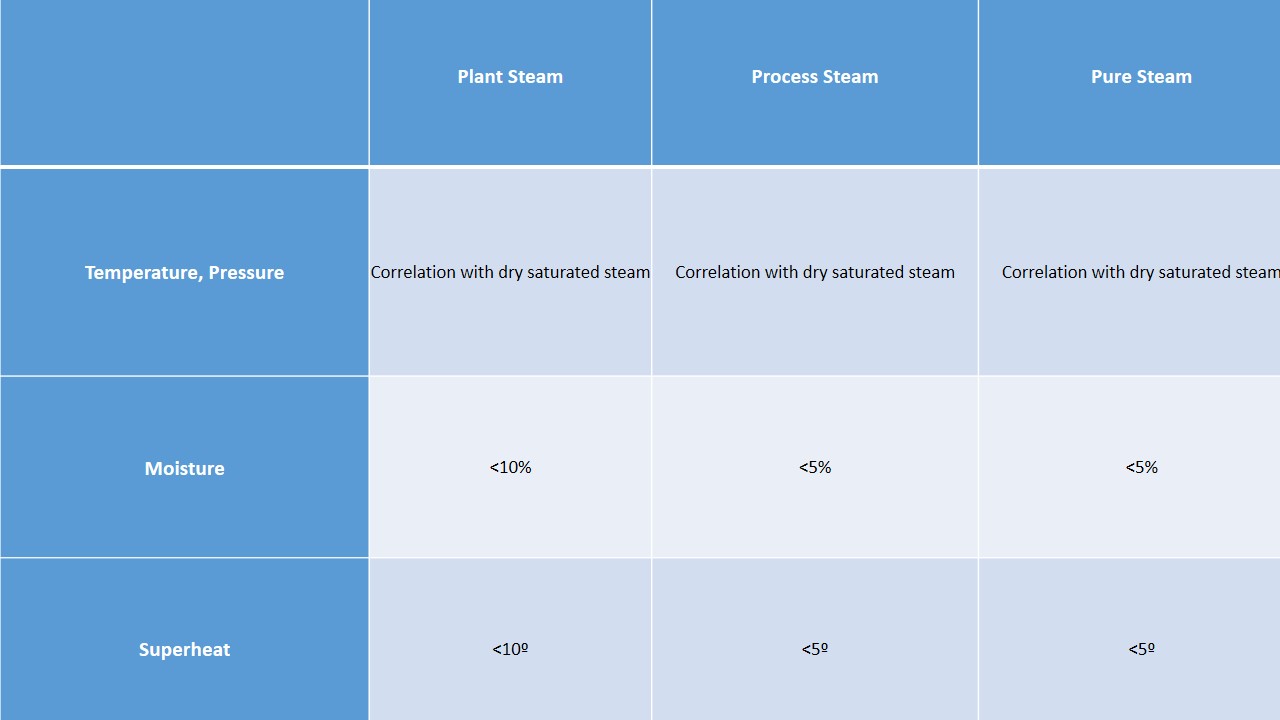

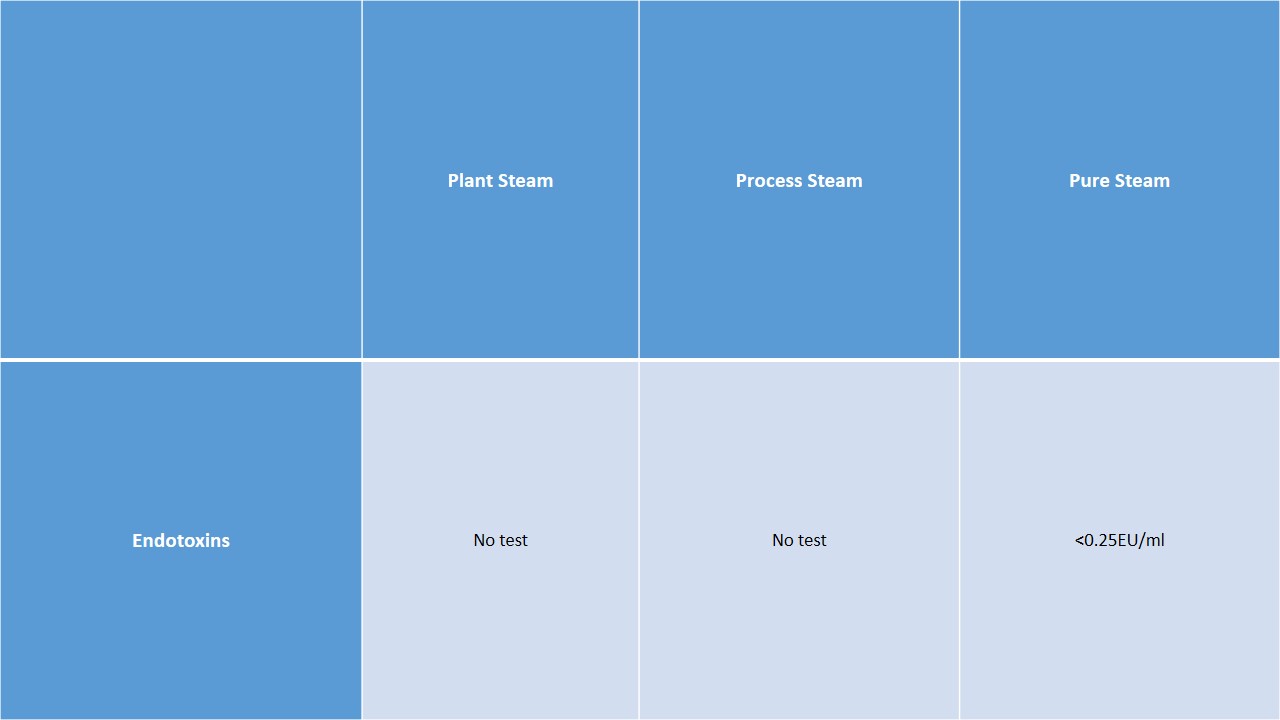

What are the characteristics of each steam?

Depending on whether the steam is pure, clean or industrial type, its characteristics are different.

Below some tables showing the different steam requirements:

Chemical requirements:

Physical requirements:

Biological requirements:

Which steam to use according to the sterilization process?

The steam quality is normally chosen according the process sterilization:

- For Pure Steam Sterilization, Pure Steam is required to inject inside the autoclave, as it will be in contact with the elements to sterilize. However, plant steam could be used for autoclave jacket, as there is no direct contact with the product.

- For Superheated Water Sterilization, the water recirculating inside the autoclave is heated through a heat exchanger, heated by plant Steam because there is no contact with the products to sterilize. However, pure steam should be used if a SIP (Sterilization In Place) is required for the filters.

- For Ethylene Oxide Sterilization or ETO, Pure steam is also required, even if clean steam is often used in the sterilization plants, and then tolerated. In that case, the steam is only used to open the spores and help the gas to be effective annihilating the micro-organisms.

To get good results for your sterilization process, the steam quality is essential.

To get good results for your sterilization process, the steam quality is essential.

RSD is an engineering company specialized in sterilization process. Don't hesitate to contact us for any sterilization projects or doubts you could have. We look forward to answering them!