Our ethylene oxide sterilizers, exclusively for pharmaceutical and Medical device industries

21/04/21

RSD has become one of the major EtO industrial equipment supplier worldwide.

Find out one of our EtO chamber that has been designed, manufactured, controlled, and qualified for a multinational medical device company.

Turnkey project of EtO industrial sterilization equipment

As experts in Ethylene Oxide sterilization, we use to collaborate with pharmaceutical, MD and EtO contract sterilization companies to manufacture EtO sterilizers of large capacity, fully equipped.

We offer comprehensive EtO sterilization solutions of high quality, extremely safe and fulfilling all the international directives and standards.

Our turnkey EtO sterilization projects

We deliver full sterilization units with their ancillary modules based on a modular design to decrease the potential risk of explosion. Our EtO sterilization equipment usually include:

- ETO autoclave

- Vacuum pump skid

- ETO vaporizer

- Air and Inert gas heater

- Gas dispensing system

Also, we propose a wide range of options to get an EtO sterilization installation complete and effective. Below, our main options:

- Preconditioning & aeration cells

- GMP Steam generator

- Automatic conveyor system

- EtO monitoring system (LEL/PPM)

- Parametric release

- Jacket cooling system

- Catalytic system (<1ppm)

- Proportional pneumatic valves

- Etc

Any project is customizable as we offer a very flexible design, based on the customer’s requirements.

Have a look to our ethylene oxide sterilization equipment with the following video.

EtO sterilization equipment manufacturer

We design, manufacture, qualify and install high-quality EtO sterilizers, based on advanced technology and innovation. These equipment are exclusively manufactured for the pharmaceutical and MD industries, as well as for EtO sterilization contract companies.

To fulfil the sector requirements, our EtO sterilization turnkey solutions are totally adapted to the customer’s needs, yielding a high level of safety, reliability, and productivity.

Therefore, our equipment fulfils the cGMPs guidelines set up by the EMEA and FDA, the safety of pressure vessels (2014/68/UE) and explosion risks (ATEX, 2014/34/UE); and meet the most stringent regulations and standards from Europe, USA, and other countries.

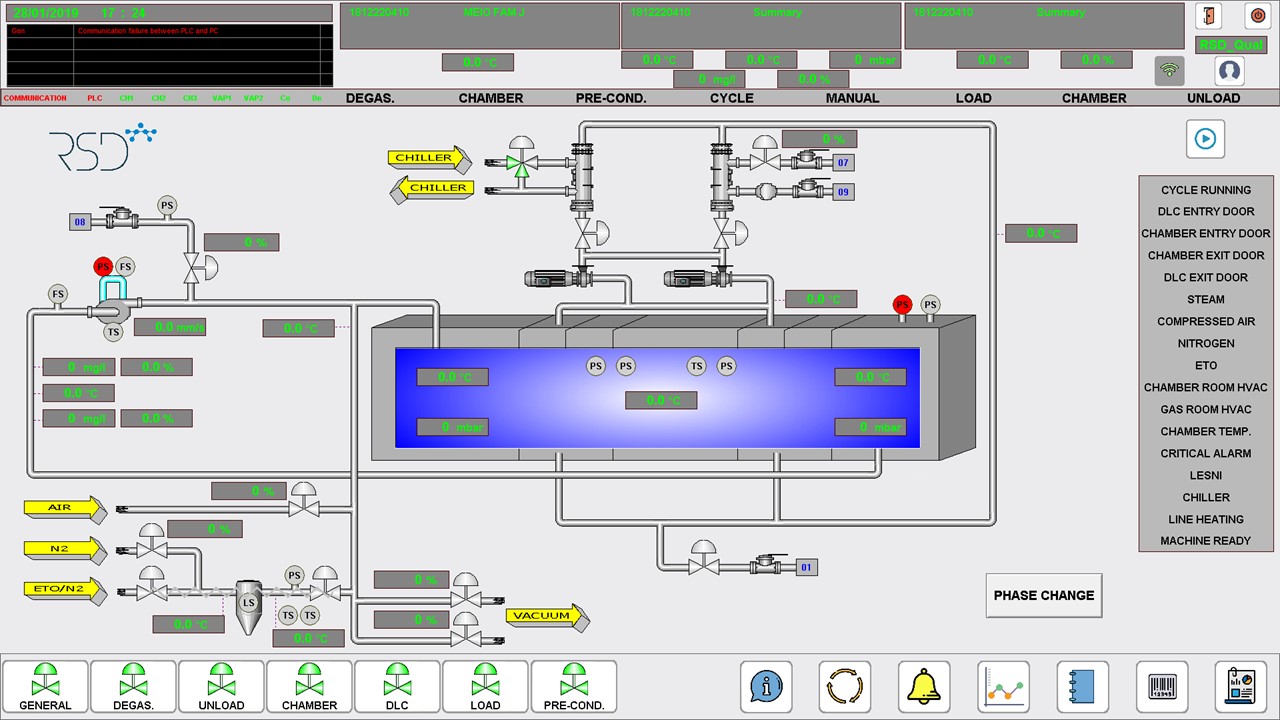

Our Control system: ONYX, exclusive for EtO sterilizers

We have developed our own control system “ONYX”, based on SCADA technology, and programmed according to the HAZOP analysis and SIL definition for each project.

We have developed our own control system “ONYX”, based on SCADA technology, and programmed according to the HAZOP analysis and SIL definition for each project.

ONYX meets customer’s needs while ensuring a safe process, below its major characteristics:

- It fulfils GAMP 5 and 21 CFR Part 11 for electronic records.

- Can create flexible recipes.

- Management of the whole sterilization interlocks.

- Displays for synoptics, graphs, alarms, recipes, processes.

- It proposes different password-protected user levels.

- Specific screen for calibration operations.

- …

More information about our control system ONYX.

RSD attends any aspect of industrial sterilization projects. With RSD, you work with a single, trusted partner that gives you full support, and controls every step of the project, to provide reliable and safe EtO sterilization equipment.

Do not hesitate to send us your enquiry!